Newsletter Sumary

- Quality Show : from September 10th to 12th

- Calibration : Insure proper specifications are met without outsourcing.

- Data Acquisition : Your test equipment does the physical work for you, avoid data entry ...

- Spring Testing : Why it can be critical in assembly

Watch our Products Videos

Chicago Quality Show

The Quality expo Show in Chicago is one of the largest industrial test and measurement shows in the US. It is an event that collects the “most comprehensive and state-of-the-art” technologies into one arena for visitors and like-minded associates to learn more on the latest in testing / measurement products.

The Quality expo Show in Chicago is one of the largest industrial test and measurement shows in the US. It is an event that collects the “most comprehensive and state-of-the-art” technologies into one arena for visitors and like-minded associates to learn more on the latest in testing / measurement products.

From September 10th to 12th

Come and visit us in booth 363.

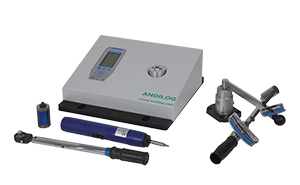

Torque Wrench / Screwdriver Calibration.

Insure proper specifications are met without outsourcing.

To be sure you are applying the specified torque on your assemblies, be accurate and check your tools. . ComTen / Andilog will provide the right tools to do that in your manufacturing area without waiting for the results.

To be sure you are applying the specified torque on your assemblies, be accurate and check your tools. . ComTen / Andilog will provide the right tools to do that in your manufacturing area without waiting for the results.Our Centormeter H series (see page) allows you to calibrate and check all of your small capacity torque measuring instruments: torque wrenches, torque screwdriver, screw gun, compression and tension system, force gauges, etc. These tools are essential in ensuring the quality of your measurements throughout the lifetime of your instruments.

The new version of the Centormeter equipment verifies the regulating torques of screw guns. This includes electric, pneumatic and hydraulic screw guns whose rotational speed can be regulated up to 3,000 RPM.

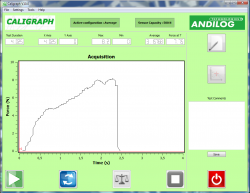

Data Acquisition

Your test equipment does the physical work for you; avoid data entry and miscalculation by allowing it to do that work as well.

Our Caligraph software is the perfect extension of our Centor series force and torque gauges. This all new easy to use and intuitive Windows software is designed to help you with graphing, analyzing, storing and reporting your tests.

Spring Testing

Why it can be critical in assembly

Most of the time, springs are used in a mechanism that has a rest position and an operating position.

Measuring forces of springs is one of the most important tests to determine the quality of the springs.

Most of the time, springs are used in a mechanism that has a rest position and an operating position.

Measuring forces of springs is one of the most important tests to determine the quality of the springs. All springs are designed to have an expected force at a particular height.

It is essential for your assembly to validate the calculations and especially the manufacturing parameters by measuring forces.

ComTen / Andilog produces a large range of spring testers , so during Quality Expo live demos are available on both our

Springtest II specially designed for very small springs (frm 0.5 to 10lbs)

and Springtest T I for quick tests in production.

ComTen / Andilog produces a large range of spring testers , so during Quality Expo live demos are available on both our

Springtest II specially designed for very small springs (frm 0.5 to 10lbs)

and Springtest T I for quick tests in production.

ISO Certified 9001:2008

ISO Certified 9001:2008